1. Aluminum LED heat sinks;

2. LED heat sink can be supplied to customers’ drawing or samples;

3. We can work with AutoCAD drawing and solidworks format;

4. Heat sink holes deburred, Surfaces free of scratches;

5. led lamp cup with tolerance of 0.5 mm are available;

6. The most advanced test equipments to ensure thequality;

7.Priceis strictly based on your design and requested quantity;

8. Your partsdeliveredto your requirements.

9.Component Application: lighting industry

10. We are focused on cost savings, quality and on time delivery.

| Production Description |

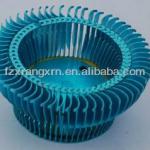

| - LED heat sink made of aluminum 1070.

- This type of heat sinks is mostly used in spotlights.

- The surface is realized by forging, CNC turning.

- Quality assurance.

| | Name | Value | | Application | spotlights | | Model | F0931 | | Production Capacity | 50000 Piece/Pieces per Month | | Finish | silver color anodizing | | Process | forging, CNC turning | | Material | Aluminum 1070 | | Place of Origin | China | | Year | 2012 | | Certification(company) | ISO 9001:2008 | | Dimension(L*W*H) | 100(dia.)x35(H) | | Type | custom forging, CNC turning | | MOQ | 5000 pieces |

|

|

| Application |

- These kinds of LED heat sinks are used in spotlights.

| |

|

| Shipping |

- EMS

- EXPRESS: around 5-7 working days to arrive

- INTERNATIONAL AIR MAIL: around 2-4 weeks to arrive

|

|

| Payment |

- PayPal

- Credit Card

- Wire Transfer

- West Union

|

|

| Packing |

| After inspection, the sinks are packed in paper box and then carefully packed in cartons. | |

|

| Services |

| | NOTE: The parts only present the machining capability in Foxron, not for sales purpose! |

|

| About US |

| We have more than 6-year experiences on CNC machining service. We are a typical China supplier and have worked formedical instrument, photo-electricity communications, automotive parts, and home appliance. We also have office in Hong Kong to meet customers' needs. |

|

|

| Our service\Buyer Guidelines

Our strongest point is that we consult. So anything you want to know about our CNC machining service, please ask us! |